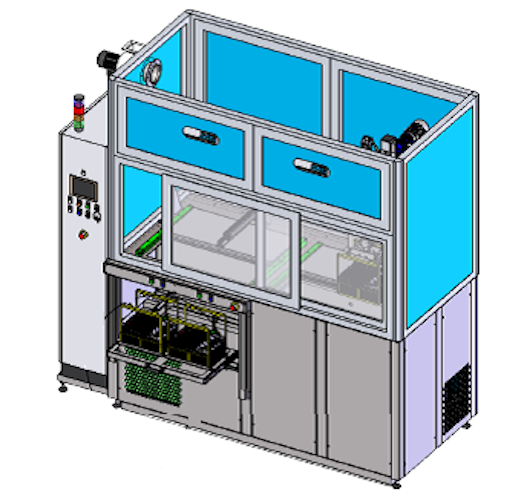

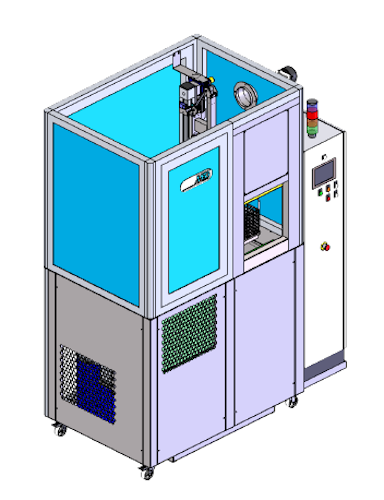

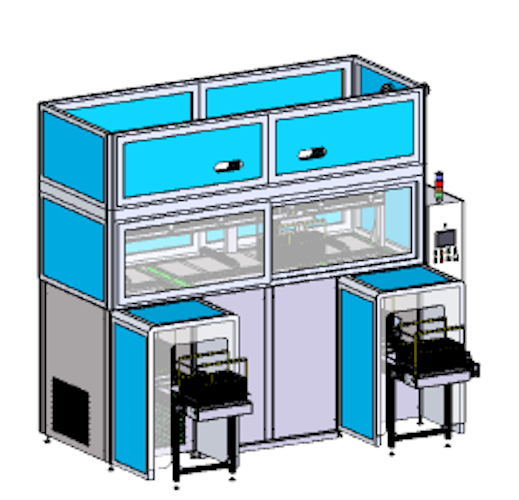

Enclosed Automatic Ultrasonic Equipment

Cleanseal Ultrasonic Cleaning Systems

-

✅ Key Features of Cleanseal Ultrasonic Cleaning Systems

🧼 Superior Mono & Co-Solvent Cleaning

Designed for use with MicroCare’s Tergo™ precision solvents, delivering outstanding cleaning results across a wide range of contaminants.

🌡️ Three-Stage Cleaning Process

Combines boiling immersion, ultrasonic agitation, and vapour rinse for consistently spotless, dry components in every cycle.

🔧 Available in Standard Sizes - Scalable designs to meet various throughput needs and component dimensions—from labs to full production lines.

🛠️ Advanced Safety Systems - Integrated safety interlocks protect against high vapour levels, low solvent conditions, and overheating—ensuring safe, compliant operation.

🧊 Refrigerated Cooling System - Maintains optimal cleaning performance with efficient thermal regulation.

🔄 Fully Automated Cycles PLC-controlled cleaning sequences ensure repeatable, high-quality results with minimal operator input.

💨 Tergo™ Solvent Compatibility - Fully compatible with the entire MicroCare Tergo™ solvent range, including PFAS-free and halogenated options.

🔊 Ultrasonic Immersion Technology - Powerful ultrasonic cleaning penetrates blind holes and complex geometries for precision-level cleanliness.

📲 Touchscreen PLC Interface User-friendly control panel with customizable programs and real-time system feedback for ease of use.

🧱 Enclosed Chamber Technology Reduces emissions and enhances safety by isolating the cleaning process in a sealed chamber.

🌀 Enclosure Ventilation - Available for safe operation.

💰 Low Operating Costs - Energy-efficient design for reduced solvent usage, lower energy bills, and environmentally conscious cleaning.

🔧 Automated Solvent Fill + PLC-Controlled Heating - Includes electric heating and fully automated fill cycles to simplify daily operation and maintenance.

🛞 Mobile Design - Equipped with wheels for easy relocation across workstations or departments.

🧪 Free Cleaning Trials Test your specific application with MicroCare Tergo™ fluids—risk-free evaluations available.

🧑🔧 UK-Based Technical Support

End-to-end service from D&S Ultra-Clean, including:

-

🔧 Commissioning & training

-

🧰 Servicing & spares

-

📞 Ongoing technical support

-

🧼 Cleanseal Ultrasonic Cleaning Systems

High-Performance Enclosed Solvent Degreasing with Ultrasonics

At D&S Ultra-Clean, we proudly supply the Cleanseal range from MEG S.r.l.—a premium line of enclosed ultrasonic solvent cleaning systems engineered for precision, safety, and sustainability. Compatible with non-flammable halogenated solvents like MicroCare’s Tergo™ series, Cleanseal units offer advanced cleaning in a fully enclosed design.

🔧 Available Models

-

✅ Cleanseal M – Mono-solvent ultrasonic cleaning

-

✅ Cleanseal C – Co-solvent ultrasonic cleaning

🧼 Mono-Solvent vs. Co-Solvent Systems

✅ Cleanseal M – Mono-Solvent Cleaning

-

Uses a single non-flammable solvent (e.g., Tergo™ MCF, HDF, or PFAS-free XCF2/XCF3)

-

Features a single process chamber with vapor-phase and ultrasonic agitation

-

Ideal for precision cleaning, high throughput, and low operational cost

✅ Cleanseal C – Co-Solvent Cleaning

-

Dual-sump system for increased solvency power or elevated cleaning temperatures

-

Compatible with Tergo™ PF100/IPA blends + hydrocarbon solvating agents

-

Best for heavy-duty cleaning: fluxes, oils, waxes, and stubborn contaminants

🌍 Sustainable & Regulatory Compliant

-

🔥 Non-flammable solvent operation

-

🌱 Low Global Warming Potential (GWP)

-

👷 Reduced operator exposure

-

🟢 Ultra-low carbon footprint

-

✅ Fully REACH & F-Gas compliant

🔬 Precision Applications

-

✈️ Aerospace & Defence – Engine parts, avionics, structural components

-

🏥 Medical Devices – Surgical tools, implants, lab instruments

-

🚗 Automotive & Optical – Lenses, sensors, and transmission parts

-

💻 Electronics & PCBs – Flux, solder paste, and contaminant removal

-

⚙️ Precision Engineering – High-tolerance components

📞 Full-Service Technical Support

Our UK-based engineering team offers:

-

🧪 System commissioning & setup

-

🧑🏫 Operator & maintenance training

-

🔧 Preventative maintenance & rapid breakdown support

-

🌐 Remote diagnostics & technical assistance

Cleanseal delivers advanced ultrasonic cleaning technology for critical applications—without compromising safety, sustainability, or compliance.