Ultrasonic Aqueous Equipment Range

Ultraclean Bench Top

🔑 Key Features of Our Ultrasonic Cleaning Systems

✅ Compact & Portable Design

Easily relocatable for flexible use across workstations and labs.

📡 Advanced Ultrasonic Technology

Equipped with piezo-electric ceramic transducers for stable, reliable ultrasonic performance.

🌡️ Digital Temperature Control

Precise heating with user-adjustable settings to optimize cleaning efficiency.

⏱️ Adjustable Cleaning Cycles

Customizable ultrasonic timers to suit various contamination levels and part sensitivities.

💧 Built-In Safety Protection

Low-liquid level sensors protect internal components from damage during operation.

🔁 Easy Maintenance

Fitted with a manual drain valve for quick, mess-free emptying and cleaning.

🧼 Optional Add-Ons

Upgrade with filtration and oil separation systems to extend fluid life and improve performance.

🛡️ Peace of Mind Warranty

Backed by a 2-year manufacturer’s warranty for confidence and long-term reliability.

⚙️ Ultraclean™ Bench-Top Ultrasonic Cleaners

Compact Power. Precision Cleaning. Trusted Performance.

Ultraclean™ bench-top ultrasonic cleaners provide high-performance cleaning in a portable and space-saving format—perfect for laboratories, repair shops, medical practices, and precision workshops.

🛠️ Built to Last

Constructed from 304-grade stainless steel, offering durability, corrosion resistance, and easy maintenance—even in demanding environments.

📏 Multiple Sizes Available

Available in tank capacities from 4L to 80L, allowing you to match the right unit to your specific cleaning volume and part size.

💧 Eco-Friendly Cleaning

Designed for use with biodegradable, water-based detergents, delivering effective results with minimal environmental impact.

🔬 Ideal for Precision Cleaning Applications:

✅ Jewellery and watch components

✅ Optical lenses and instruments

✅ Laboratory glassware

✅ Dental and surgical tools

✅ Small mechanical parts and assemblies

Whether you're cleaning fine contaminants from delicate components or degreasing metal parts, Ultraclean™ systems deliver consistent results with minimal operator effort.

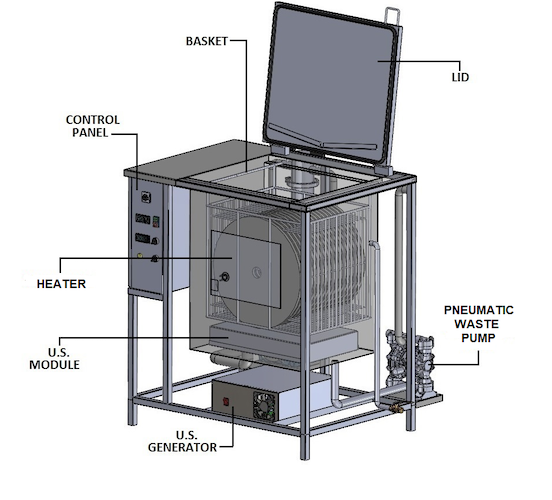

Cleanline Single-Stage

-

📏 Flexible Tank Sizes

🟢 Available in 60L, 90L, 120L, 180L, and 240L models to suit your cleaning requirements.

🔒 Energy-Efficient Lid

🟢 Insulated, hinged stainless-steel lid retains heat and reduces energy loss.

🌡️ Digital Temperature & Process Timer

🟢 Precise digital temperature control

🟢 Integrated ultrasonic cycle timer for repeatable results.⏱️ 24/7 Automated Operation

🟢 Built-in automatic start/stop timer – schedule cleaning cycles to suit your production workflow.

🚨 Liquid Level Protection

🟢 Integrated low liquid level sensor ensures safe and reliable operation.

💧 Manual Drain Valve

🟢 Effortless tank draining for easy maintenance and fluid changes.

🛠️ Optional Add-ons

🟢 Customise with oil separation, filtration, detergent dosing, basket agitation, and auto-fill systems.

🎯 Optimised for precision cleaning in aerospace, automotive, manufacturing, and electronics industries.

📩 Need help choosing the right model? Contact us or Request a quote

⚙️ Single-Stage Aqueous Ultrasonic Cleaning Systems

Cleanline single-stage aqueous ultrasonic cleaning systems are engineered for high-performance precision cleaning, offering a cost-effective solution for a wide range of industrial applications. Ideal for inter-stage processing, final component cleaning, and repair or overhaul tasks where rinsing is not required, these systems deliver consistent, reliable results.

Constructed from high-quality stainless steel, Cleanline ultrasonic tanks are available in a variety of capacities, ranging from 60 to 240 litres, making them suitable for diverse production environments.

A comprehensive selection of optional features is available to enhance functionality and efficiency, including:

✅ Key Features:

-

🧼 Modular Configurations – Choose from washing, rinsing, passivation, and drying stages

-

🔄 Manual or Automatic Operation – Available in user-friendly manual format or fully automated versions with basket handling

-

⚙️ Stainless Steel Construction – Built for durability and long-term performance in demanding environments

-

🔊 High-Efficiency Ultrasonics – Equipped with piezo-electric ceramic transducers for uniform cleaning

- ⚙️ Oil separation systems

-

🌡️ Digital Temperature & Process Control – Integrated temperature controllers and timers for process repeatability

- ⚙️Basket agitation

-

📐 Custom-Built Solutions Available – Tailor the tank sizes (60 to 240 litres) and layout to your specific cleaning needs

-

🔧 2-Year Warranty – Confidence in long-term performance and support

Applications:

-

✅ Aerospace, automotive, and medical component cleaning

-

✅ Complex geometry and blind holes

-

✅ Contaminants such as oils, particles, flux residues, and polishing compounds

Whether you need a compact manual system or a fully automated turnkey solution, Cleanline multi-stage ultrasonic systems provide a scalable, cost-effective answer for demanding cleaning environments.